“The Ideas Program” - Learning from the Portsmouth Naval Shipyard

Carleigh listens to Paul OʼConnor describe the collective effort to save the Portsmouth Naval Shipyard

On Saturday, the Seacoast Shipyard Association celebrated the 20th anniversary of the successful fight to save the Portsmouth Naval Shipyard. Paul O’Connor, the former head of the Metal Trades Union, was a central figure in ensuring the local yard escaped closure during the 2005 round of Base Realignment and Closure (BRAC). O’Connor worked with the Metal Trades Council and John (JJ) Joyal, the Vice-President of the AFGE and a welding instructor and fourth-generation shipyard worker to successfully fight for the shipyard.

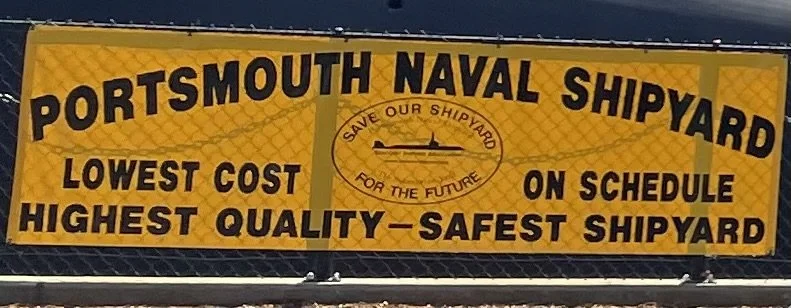

Paul spoke at the ceremony on Saturday about the importance of every workerʼs contribution to saving the yard, not just by fighting back, but by doubling down on what they did best—doing the very best work, below budget and ahead of schedule. As the yellow banner hanging on the fence in front the USS Albacore (a must-see for anyone who hasnʼt toured it) proudly states: “Portsmouth Naval Shipyard: Lowest Cost, On Schedule, Highest Quality—Safest Shipyard.”

Carleigh was curious about how the shipyard workers were able to support those claims in their fight to keep the base open, so she struck up a conversation with a couple of retired workers. Two of them relayed the fascinating story of the MCMs or Material Control Mechanics. Essentially, workers at the shipyard discovered that mechanics were sacrificing time and resources by doubling back for the parts they needed, and they devised a system where trained personnel would purchase all the parts necessary for a job, store it in a bin, and ensure that each necessary part was available when the mechanics needed it. Despite interference from supervisors who distrusted the new system, the MCMs succeeded in saving the shipyard $6,000,000 in the first year of the program!

The MCMs were part of the “Ideas Program.” As Paul explains,

“The program was simple in its concept but not so simple in the amount of work necessary to shift the shipyardʼs cultural stereotypes regarding whose ideas were worthy of implementation. Our “Ideas Program” primary tenet was; ‘Listen to the men and women doing the work. Men and women at the job site have the best ideas on creating efficiency at the job site.’

It sounds so simple and so basic, right? But too often in industry, workersʼ ideas are ignored and ideas from people with no on-the-jobsite experience have their ideas adopted. Thatʼs less about creating efficiency and more about egos and cliques.

We worked to shift the thinking at the shipyard from a fear-based work environment to a values-based work environment and our performance, productivity, and morale vaulted as a result.

The MCM was one of the many ideas from our men and women at the job site.

One of the biggest pitfalls of cultural change is sustainment but ultimately any cultural shift requires champions and for those champions to inspire and cultivate future champions and on and on (not enough of that going on in Congress, by the way).”

Paul and Carleigh share a passion and a history of working to promote collaboration, respect, and dignity at the jobsite. Whether it is for the graduate student workers who power institutions of higher learning or the men and women who build and maintain the US Navyʼs submarine fleet, leadership means working together to overcome fear, cliques, and partisanship, and build sustainable coalitions around our shared values.